As urbanization levels increase and more and more land is used up, alternative storage methods are more necessary than ever. Expanding your storage space horizontally is not always possible, and thus, other options must be considered, especially if you are operating a growing business. One key change to think about is beginning to utilize available vertical space, building “up” rather than “out.” Utilizing vertical storage systems not only increases your available floor space but also provides a streamlined and organized environment that can significantly improve the overall efficiency of your warehouse. Here’s what you need to know about implementing vertical storage solutions in your warehouse space!

Understanding Vertical Storage Systems

Vertical storage systems come in several different forms, each catering to specific storage needs. Here are a few types of vertical storage systems that business owners and warehouse managers should know:

Pallet Racks

While pallet racks aren’t always exclusively vertical, pallet racking systems are nevertheless one of the most important types of vertical storage solutions. Pallet racking systems use tiered racks that resemble shelves to store pallets in easily accessible locations, maximizing vertical space utilization without sacrificing valuable floor space. Pallet racking is versatile and adaptable to any warehouse layout. Selective racks provide easy access to all pallets, while drive-through and drive-in racks offer high storage density with a smaller footprint.

The best pallet racking systems for your space will depend on various factors, including your warehouse operations, inventory management goals, and available vertical height. For optimal performance, we recommend consulting with our experts for a thorough analysis. With your storage needs and goals in mind, we use our CAD (computer-aided design) computer software to create cost-effective storage solutions for a more productive, efficient, and safer environment.

Cantilever Racks

Cantilever racks are designed specifically for storing long, bulky, and irregular-shaped items. They consist of vertical upright columns with horizontal arms extending outwards. The design eliminates floor obstructions, with some options even enabling forklift operators to retrieve items from both sides. This type of rack system is optimal if your warehouse stores lumber, pipes, metal bars, furniture, and other oversized materials. They offer high storage capacity and efficient use of warehouse space, especially when dealing with items that don’t fit standard pallet racking but still need to be kept off the warehouse floor to save space.

Vertical Carousels

Vertical carousels are specific types of automated storage and retrieval systems (AS/RS) that consist of a series of vertically rotating shelves. When an item is needed, the vertical carousel system automatically brings the desired shelving units to the operator, lowering higher shelves for efficient use. These automated systems save time by eliminating the need for workers to search for items, significantly increasing picking efficiency. Perfect for small parts, perishable items, and inventory with high turnover, vertical carousels and similar automated storage systems increase productivity and storage space at the same time.

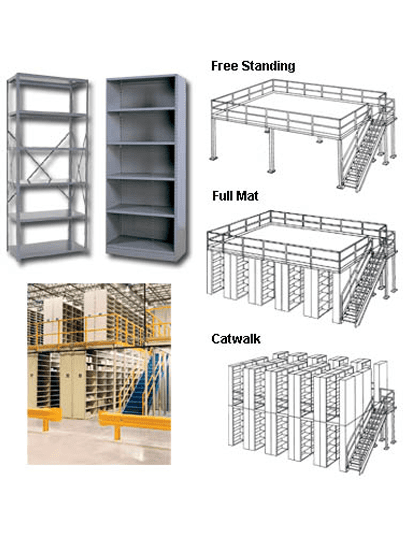

Mezzanines

While not storage solutions by themselves, mezzanine platforms offer a practical and cost-effective use of vertical space by introducing an additional level without raising the roof of the building or sacrificing valuable floor space. This added space can be used to increase storage capacity, protect valuable inventory, or serve as an office area and observation deck.

The Benefits of Vertical Storage Solutions

Added Storage (No Extra Floor Space Required!)

Arguably the most important benefit of implementing vertical storage solutions is the ability to make the most of your vertical space, which is frequently underutilized in industrial storage settings. By expanding upward instead of outward, businesses can accommodate a higher volume of goods and materials without the need for vast expansion or acquisition of additional storage space. This is especially helpful to industries dealing with limited square footage, allowing them to store more items within the same footprint.

Increased Productivity

Optimizing your inventory management has positive effects on your entire warehouse staff. When workers can quickly identify and pick orders, it helps reduce errors and enable more efficient operations.

Cost-Effectiveness

Rather than expanding your building to create more storage space, vertical storage systems enable you to build up rather than out. This is significantly more cost-effective than embarking on a new construction project.

Enhanced Accessibility

Using a vertical storage system for efficient space utilization also helps make your inventory more accessible. However, it’s important to still make time for regular maintenance, thoroughly label and document where you store items on the shelves, and invest in careful planning before deciding on a solution for your storage needs. This ensures not a single square foot is wasted!

Maximize Your Vertical Space Today!

The benefits of vertical storage in industrial settings extend beyond mere space optimization; they encompass increased productivity, cost-effectiveness, and a more organized and accessible workspace. A Diversified Rack and Shelving, we employ a team of knowledgeable pallet rack installers who are ready to help you maximize your vertical space in your warehouse.

We buy and sell many different new and used storage and space optimization solutions, including but not limited to teardrop pallet racking, drive-in and drive-through racks, mezzanines, and more. Call us today or contact us online to begin exploring your options and receive your free quote!